Autodesk Moldflow Insight Ultimate 2026 Free Download is a Insight simulation program 64-bit from Direct link. Autodesk Moldflow Insight is a highly accurate plastic injection molding software developed for engineers and manufacturers who require precision in mold and part design. Designed to run smoothly on Windows, this advanced simulation tool helps predict how thermoplastic materials behave during the molding process. Whether you’re dealing with plastic part design, mold cooling analysis, or looking for cycle time reduction, the software offers a powerful visual environment for simulating and correcting manufacturing flaws before production starts. For those working with injection molding defect analysis, Autodesk Moldflow provides a visual representation of issues such as warpage, air traps, and weld lines—helping identify potential design concerns early. With features like Moldflow Synergy and Moldflow Communicator, design teams and manufacturing engineers can collaborate better using real-time simulation data. Using Design of Experiments, users can tweak variables and improve cooling channel efficiency, ensuring both quality and performance in plastic molding simulation tools.

The integration with major CAD software makes Autodesk Moldflow Insight a preferred choice for engineers seeking streamlined workflows. Its finite element analysis engine supports both 3D simulation software and Dual Domain technology, providing accurate predictions for polymer behavior and plastic flow simulation. Users can easily switch between Moldflow Insight Premium and Moldflow Insight Ultimate, depending on project needs and simulation complexity. For those focusing on mold design optimization, the software highlights stress zones and flow behavior, allowing timely adjustments before physical tooling begins. With Windows-compatible simulation, setting up the Moldflow Insight installation is straightforward. Many manufacturers opt for the Autodesk Moldflow trial before upgrading, ensuring they have the right version tailored for their production goals. The tool is frequently used by plastic engineers looking to enhance process optimization software that meets high-precision standards. From conformal cooling to manufacturing defect prediction, the software delivers reliable insights for better decision-making. Also check out AutoCAD 3D Software.

For engineers involved in Autodesk Moldflow training or earning Autodesk Moldflow certification, the software acts as a critical tool for understanding mold dynamics and thermoplastic flow. Troubleshooting production issues becomes more efficient with access to Moldflow Insight troubleshooting modules and real-time analysis, allowing users to tackle injection molding problem solving with data-driven accuracy. Features like Moldflow cloud solving enable large-scale simulation processing without stressing local machines. Whether you’re refining a design for plastic part warpage or aiming for maximum material efficiency, Moldflow ensures optimized simulation and minimal trial-and-error in physical prototyping. With widespread use in mold design software, it’s an indispensable asset for those looking to minimize defects and material waste. Professionals rely on it not just for part modeling, but also for refining entire molding cycles and reducing production costs. Downloading from official Autodesk software download portals guarantees updated features and proper Autodesk Moldflow support, making it a trustworthy resource in modern plastic engineering software development.

The Features of Autodesk Moldflow Insight 2026 Software Free Download:

- Part Quality Prediction: Simulates and predicts defects like warpage, sink marks, and weld lines for optimized part quality.

- Mold Design Optimization: Analyzes cavity, feed, and cooling layouts to minimize rework and enhance mold performance.

- Process Optimization: Identifies ideal processing conditions to reduce cycle times and improve manufacturability.

- Advanced Material Modeling: Supports thermoplastic/thermoset materials, fiber orientation, and rheological behavior analysis.

- Multi-Cavity Analysis: Evaluates single or multi-cavity molds for consistent fill, pressure, and manufacturability.

- Flexible Solving Options: Runs simulations locally, on remote servers, or via cloud for faster design iterations.

- Specialized Molding Processes: Simulates gas-assisted, co-injection, microcellular, and compression molding methods.

- Automation and Customization: Uses scripts/API for setup, post-processing, and machine-specific process adjustments.

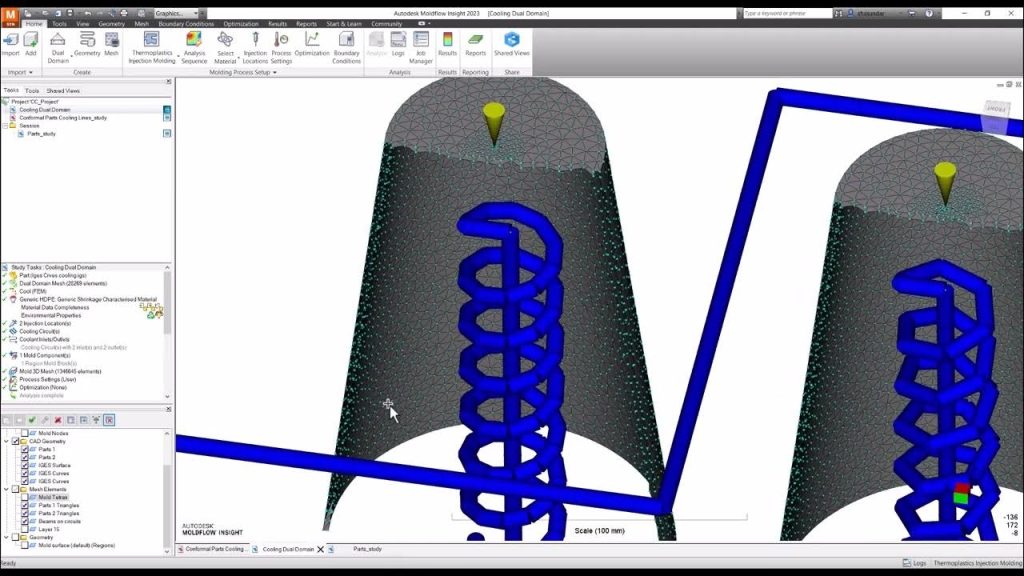

- Cooling Channel Optimization: Automatically adjusts cooling layouts for uniform temperature and reduced cycle time.

- Warpage Analysis Enhancements: Utilizes STAMP model for precise 3D warpage predictions using real shrinkage data.

- Material Database: Includes over 11,000 material grades for accurate simulation and material selection.

- Result Visualization: Customizable plots, histograms, and side-by-side result comparisons for better analysis.

- Integration with CAD/CAE: Imports native CAD files and exports results for structural analysis with tools like Helius PFA.

- Core Shift Analysis: Simulates core interactions to predict movements and prevent interpenetration.

- DOE and Parametric Studies: Conducts Design of Experiments to optimize part, mold, and process parameters.

- Valve Gate Control: Supports velocity-controlled valve gates for precise flow management in 3D simulations.

- Assembly Analysis: Simulates warpage under real assembly conditions for improved design accuracy.

- Birefringence Analysis: Evaluates optical properties to assess stress-induced effects in molded parts.

- Sink Mark Prediction: Displays positive and negative sink marks for comprehensive defect analysis.

- Moldflow Communicator: Shares simulation results with stakeholders for visualization and collaboration.

Technical Setup Detail of Autodesk Moldflow Insight Ultimate 2026 Full Version:

| Attribute | Details |

|---|---|

| Software/Game Name | Autodesk Moldflow Insight 2026 |

| File Name | Autodesk_Moldflow_Insight_2026.zip |

| Created By | Autodesk Inc. |

| Publisher | Autodesk Inc. |

| Developer | Autodesk Inc. |

| Version | 2026 |

| License Type | Subscription-based (Flex or Named User) |

| Release Date | March 26, 2025 |

| Category | Engineering Simulation Software |

| Language | English (and other regional languages) |

| Uploaded By | Autodesk Inc. |

| Official Website | https://www.autodesk.com/products/moldflow/overview |

| File Size | Approximately 2.65 GB (for Moldflow Communicator 2026.0) |

| File Type | Executable (.exe) or Compressed Archive (.7z) |

| Compressed Type | 7z (for Moldflow Communicator 2026.0) |

| Supported OS | Windows 10, Windows 11, Red Hat Enterprise Linux (RHEL) 8.6 and higher |

| Compatibility | Autodesk Moldflow Insight 2026 is compatible with Autodesk Moldflow Synergy 2026 and other Autodesk products |

| Permissions | Administrator privileges required for installation |

| Graphics Card | Certified graphics hardware recommended (e.g., NVIDIA Quadro series) |

| Display Resolution | 1920 x 1080 pixels or higher |

| Internet Connection | Required for activation, updates, and cloud-based features |

| Mouse | 3-button mouse with scroll wheel recommended |

| Keyboard | Standard keyboard |

System Requirements of Autodesk Moldflow Insight 2026 For Windows:

| Component | Minimum Requirements | Recommended (Optimal Performance) |

|---|---|---|

| Operating System | Windows 7 SP1, 8.1, or 10 (64-bit) (UI & solver). | Windows 10 or 11 (64-bit, Pro/Enterprise editions) recommended for UI and enhanced support. |

| Linux (Solver only) | RHEL / CentOS 6.5–7.0 or higher, 64‑bit Intel/AMD. | RHEL/CentOS 7.8+ (64-bit) for better stability and compatibility. |

| Processor (CPU) | ≥ 2.0 GHz multi‑core (x64). | High-end multi-core like Intel i7, i9 or AMD equivalent, ≥ 2.5–3.0 GHz. |

| Memory (RAM) | 8 GB RAM with ≥ 4 GB virtual/swap space. | 16 GB for moderate datasets; 32–64 GB+ for large automotive-size molds or cooling analysis. |

| Graphics Card | Minimum: 512 MB VRAM, OpenGL‑capable with hardware acceleration (OpenGL 3.2+). | ≥ 2 GB VRAM, OpenGL 3.2+ certified GPU (e.g., Quadro/RTX A‑series) for reliable viewport and Synergy UI performance. |

| Storage / Disk Space | At least ~12 GB free space for installation and temp files. | SSD with 500 GB+ recommended to store large simulation outputs and reduce I/O delays. |

| Display / Resolution | Minimum display resolution 1280 × 1024. | Full HD or better (e.g. 1920 × 1200) for improved UI clarity and panel layouts. |

| Browser / UI Dependencies | Internet Explorer 11 or later (Windows UI help). | Same – ensure up‑to‑date drivers and Windows patches for Synergy/Communicator UI |

| Virtual/Swap Memory | ≥ 4 GB swap or virtual memory. | Match or exceed RAM size (e.g. 16–64 GB swap/virtual) to accommodate peak memory demands |

| Solver‑only Notes | Linux solver allowed without UI; Windows UI not supported on Linux. | For compute clusters, Linux solver on RHEL 7.8+ recommended for scalability and performance |

How to download Autodesk Moldflow Insight 2026 into Windows?

- First of all, click on below download button and shift on the download page.

- On the download page, you can easily download via Direct link using IDM.

- After downloading completed please follow the installation guide that given below

How to installed Autodesk Moldflow Insight Software into Windows PC?

- After downloading please used WinRAR Software if you have downloaded RAR or Zip file to Extract.

- After extraction please open folder and then, double click on setup.exe file and start installation wizard.

- After that, you have to accept the insallation policy and press Next.

- After that, insallation will be started.

- After installation completed please closed the installer.

- Now run your software from desktop icon and start what you went to do with your software.

- I hope you like this.

- If you like please shared this post with your friends and family on Facebook. X, LinkedIn. And So on.